Monochrome Marvels: The Enduring Appeal of Black and White LCD Displays

In today’s fast-paced technological universe, it’s easy to get caught up in the whirlwind of vibrant colors and high-definition displays. Amidst this dazzling array of visual splendor, there exists a simple and timeless charm – the black and white LCD display*or the monochrome LCD display, to be more precise). Though seemingly old-fashioned and out-dated when compared to OLED and other colored LCD screens, monochrome screens continue to captivate our attention nevertheless. Along the following lines, we will explore the enduring appeal of black and white LCD displays, why they remain relevant in our technologically advanced age, the many fascinating applications that make them truly monochrome marvels, and delve into how these remarkable displays are manufactured. Keep reading to learn more.

Their classic aesthetic

One of the primary reasons behind the continued fascination with black and white LCD displays is their classic and elegant aesthetic. While color screens can be eye-catching and vibrant, there’s something undeniably timeless about the simplicity of monochrome LCD. The sharp contrast between black and white pixels harks back to the days of early computing, evoking a sense of nostalgia for many. It’s a design that transcends trends and stands the test of time. If you were born in the 20th century, you probably still remember your first television experience when all the screens were black and white and still brought us immense joy.

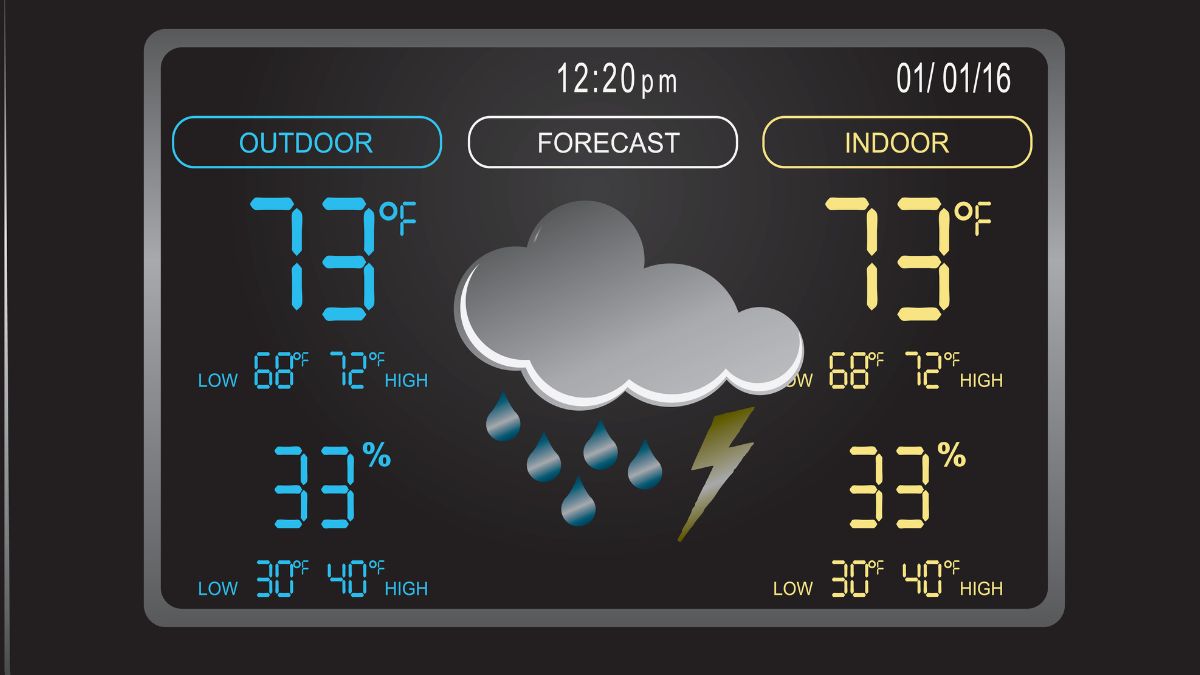

Black and white LCD displays also offer excellent legibility, a feature highly prized in a variety of applications. The high contrast between black text and a white background makes reading text on these displays easy on the eyes, even in challenging lighting conditions. This exceptional legibility makes monochrome screens ideal for e-readers, digital watches, and various industrial equipment where quick and accurate information retrieval is essential. Your digital watch would be powerless against the harsh sunlight if not for the monochromatic display.

In today’s time when energy efficiency and sustainability are an important issue for manufacturers, monochrome LCD displays shine as energy-saving champions. Color screens, with their bright and colorful pixels, tend to consume significantly more power than their monochrome counterparts. This lower energy consumption means that black and white screens can run on smaller batteries or last longer between charges, making them a practical choice for portable devices like e-readers and smartwatches.

Another aspect of monochrome LCD displays that adds to their appeal is their durability. Unlike color screens, which can be more susceptible to damage, monochrome screens are known for their ruggedness. They are less prone to burn-in and are better equipped to withstand environmental stressors, such as extreme temperatures, dust, and moisture. These qualities make them an ideal choice for industrial and outdoor applications, where durability is paramount.

While color displays tend to come with a higher price tag due to their complexity and the costs associated with color calibration, monochromatic LCD displays are more cost-effective to produce. This cost efficiency has led to their adoption in a wide range of devices, from calculators and budget cell phones to medical devices and barcode scanners. They offer the best value for basic applications where color is not a necessity.

Finally, one of the most compelling aspects of black and white LCD displays is their suitability for specific applications that demand reliability and functionality over visual flair. These displays excel in e-readers, where they mimic the appearance of printed text, reducing eye strain during prolonged reading sessions. In the medical field, monochrome screens are preferred for their precise visualization of medical imaging, ensuring accurate diagnosis. Additionally, devices like digital alarm clocks and digital watches rely on the simplicity of monochrome displays to provide essential information at a glance.

Manufacturing monochrome LCD displays

The manufacturing process of monochrome LCD displays is a fascinating journey in itself. These displays are created using a combination of liquid crystals, polarizers, and backlights. Here’s a simplified overview of the manufacturing process:

The heart of the monochrome LCD display is the liquid crystal material placed between two glass substrates. This liquid crystal layer is precisely engineered to create the pixel grid.

Then, polarizers are applied to the front and back of the glass substrates. These polarizers help control the orientation of the liquid crystals, allowing them to modulate light passing through the display. To illuminate the display, a backlight source is positioned behind the liquid crystal layer. The backlight can be an array of LEDs or a cold cathode fluorescent lamp (CCFL) that emits white light evenly across the screen.

The control electronics, including drivers and integrated circuits, are connected to the display to manage the liquid crystal pixel states, ensuring the correct display of images or text. Once all components are in place, the display is sealed to protect the delicate layers inside from environmental factors, such as moisture and dust. After the entire process is completed, the end result is a durable and high-quality screen that will serve its users for years to follow.

The final word

As explained above, the appeal of black and white LCD screens is a testament to their classic aesthetic, legibility, energy efficiency, durability, and cost-effectiveness, which makes them an essential component of 21st century technology. Their ability to meet the demands of specific applications, coupled with their timeless charm, ensures that monochrome marvels continue to hold a special place in the realm of technology for a long time. So, while we may continue to be captivated by the undeniable allure of vibrant colors, the black and white LCD display will always have its unique and cherished role in the tech world, reminding us that sometimes, simplicity is the ultimate sophistication. The manufacturing process, as outlined, adds yet another layer of fascination to these enduring marvels.